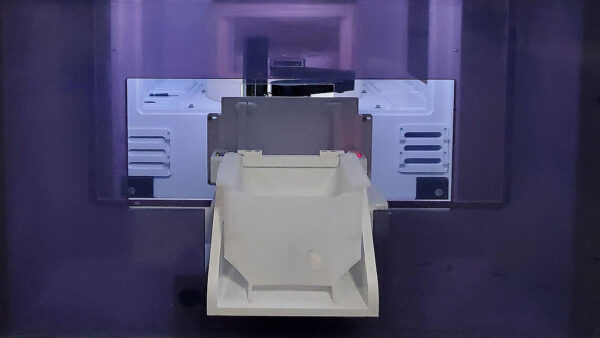

Single Wafer Processing

Inception:

RENA Inception, the semi-automated single wafer system for wet chemical cleaning and etching processes are performed highly efficiently including rinsing steps and spin drying. Applications for FEoL (Acid) & BEoL (Solvent) processing. Dual moving spray arms with separate chemical lines with multiple tank design provides multi-step processing features. Additional cleaning options, like Megasonic are available as well process features as concentration monitoring and endpoint-detection. A variation of chucks are available for different wafer and substrate sizes to allow easy setup for different application. There are many advantageous features for process control and monitoring in the IDX Flexware software. All RENA systems are available and compliant to the SECS/GEM interface of factory host.

Clean, Etch, Strip & Dry – enabling the transition from R&D up to pilot production.

Features and Benefits:

- Manual or automated wafer handling

- Wafers up to 200 mm and masks up to 7”x 7”

- Single or dual load ports

- Low utility consumption

- Small footprint dimensions

- Highly flexible software enables rapid process development