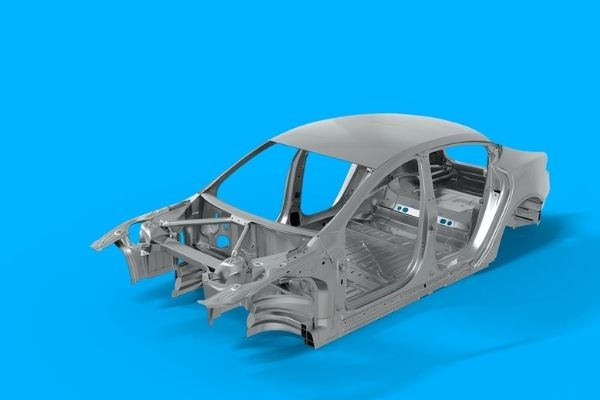

Weld Seam AOI Inspection Car Body Manufacturing

Defect-Free Car Bodies Thanks to Laser Seam Inspection.

A single imperfect roof seam can render an entire car body unsellable– but this is a cost that can be avoided! Weld seam inspection ensures that only perfectly welded car bodies leave your production line. This, in turn, guarantees optimal customer satisfaction and protects your brand image.

Weld seam inspection reliably detects all welding defects in the car body – on both visible and invisible seams. Even the slightest defects are detected – immediately after the welding process. This means that corrective actions can be swiftly implemented. The end results are reduced costs thanks to early intervention, satisfied customers thanks to high quality standards, and no nasty surprises caused by late detection of defects.

Better Vision with Automation: Today’s cutting-edge technology uses automatic welding. Efficiency is increased even further when the inspection of weld seams is also fully automated. The benefits are clear. Automated weld seam inspection is always reliable and objective. Every weld seam is automatically inspected after each manufacturing step and product quality is also documented.

VITRONIC uses laser triangulation technology. This allows laser seams and fine brazed seams to be inspected quickly and with high resolution in 3D. Seam detection presents a particular challenge with flat car body seams. VIRO WSI clearly identifies the tiniest geometric and cosmetic deviations.

Inspection range

- porosity

- weld width

- seam interruption

VITRONIC welding seam inspection systems have been successfully used by leading OEMs and tier-1 suppliers across the globe since 1995. They regularly rank VITRONIC in first place in internal comparison tests. VITRONIC leads the market in weld seam inspection and sets the benchmark with VIRO WSI.

Weld Seam Inspection with VIRO WSI for Car Body Weld Seams

- 100% inspection

- Maximum product quality

- Process optimization through data analysis

- Potential cost reductions

- Avoidance of serial defects

- Maximum availability (24/7)