Condensation Soldering-Condenso Series

Description:

In condensation reflow soldering, or vapor-phase soldering, soldering is accomplished using a hot vapor. Heat transfer in condensation soldering is up to ten times higher than in convection soldering. This makes it particularly suitable for processing large or high-mass boards in a stable process atmosphere. The inert heat transfer medium used is perfluoropolyether (Galden®).

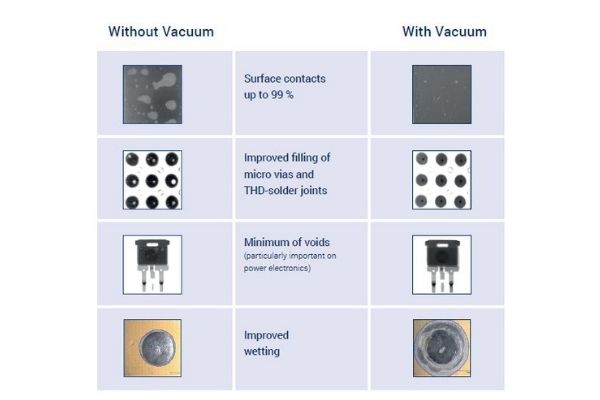

Our Condenso series can solder even the most difficult assemblies quickly and dependably, at temperatures up to 240°C. In order to improve control of the condensation phase, Rehm has developed a patented injection process that allows the soldering procedure to be individually regulated. An optional vacuum module ensures void-free soldered joints – directly after the soldering process or as a pre-vacuum. Our systems let you adjust all parameters, such as pressure or temperature, flexibly – for the best soldering results that exactly match the requirements of your manufacturing.

Condensation features:

- Reproducible control of the reflow profile with patented injection principle

- Hermetically sealed processed chamber

- Controllable vacuum process / horizontal transport for safe conveying of module through the machine

- Horizontal transport for safely guiding the assembly through the system

- No spreading of Galden® and active Galden® filtering

- Active process monitoring with wireless WPS system and the latest software tools

Condensation Soldering Systems:

CondensoXC: Space-saving and powerful

- Batch system for low throughput

- Used in laboratory applications, small production lines or prototyping

CondensoXS smart: Great performance with a small footprint

- Inline ready system for medium throughput

- Low space requirements

- Ideal for small-series production

CondensoXM smart: All-rounder for electronics production

- Inline system for medium throughput

- Automatic side Loading/unloading with pre-assembled carriers

- Used for small and medium-sized series

Condenso smartline: Ideal for large series

- Inline connection for medium throughput

- Automatic loading, internal carrier return transport

- Used in series production

CondensoX-Line: Reliable in the through-feed process

- Inline system for high throughput

- 3-chamber system and built-in vacuum soldering

- Series manufacture and power electronics

- Fully inert soldering process under nitrogen