2D & 3D CT X-Ray Inspection Systems

Description:

Electronics are a major component of almost every modern product these days. From Automotive to Aerospace, Medical to Munitions. Our team is ready to help your team take a deeper look inside your most quality-critical components, to know what’s working and what isn’t.

Our 2D and 3D Computed Tomography (CT) X-ray inspection technology will fill your quality reports with the data-driven insight you used to think was impossible. You’ll get a better picture from every angle:

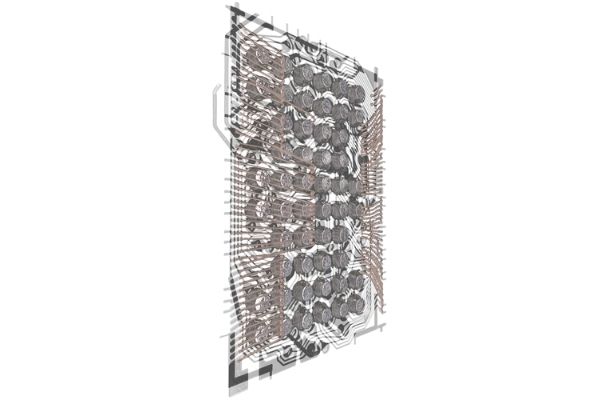

- CT scan of broken bond wires, delamination issues and solder joints

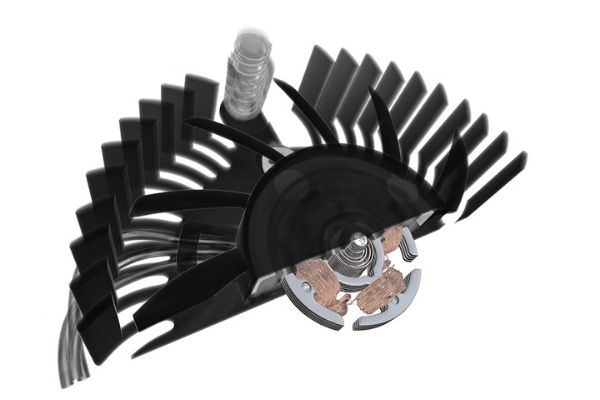

- Check for foreign object debris (FOB) that’s detrimental to electric motor performance

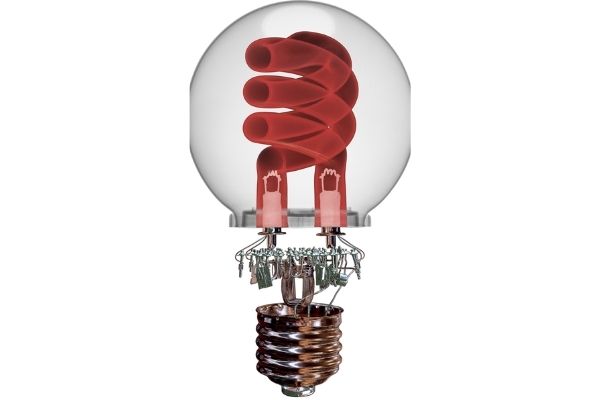

- Inspect welding used to encase lithium batteries to check for wall thickness, and much more

X25 INDUSTRIAL CT X-RAY INSPECTION SYSTEM

Compact & Efficient

The X25 is quite possibly the most conveniently sized industrial CT system on the market. The system offers all of the same features as the larger systems while still maintaining the ability to fit through a standard interior door. The X25 is well suited for small to medium sized objects.

- Ideal for submicron X-ray and CT applications

- X-ray Energies from 10 kV – 160 kV

- Geometric Magnification: >2000x

- Overall Maximum System Resolution: ~500 nm

- 6 in (15 cm) diameter x 9 in (22 cm) tall nominal part envelope

X25 Applications

- Failure Analysis

- Assembly Verification

- Reverse Engineering

- Density Analysis

- Finite Element Analysis

- Void and Porosity Analysis

- 2D and 3D Metrology

- Internal and External Measurements

- Product Quality Compliance

- Research and Development (R&D)

- 3D CAD comparisons

- Weld and Braze Quality Analysis

- In Situ Monitoring

- Additive Manufacturing System Qualification