POF Cable Processing Fully Automatic

Description:

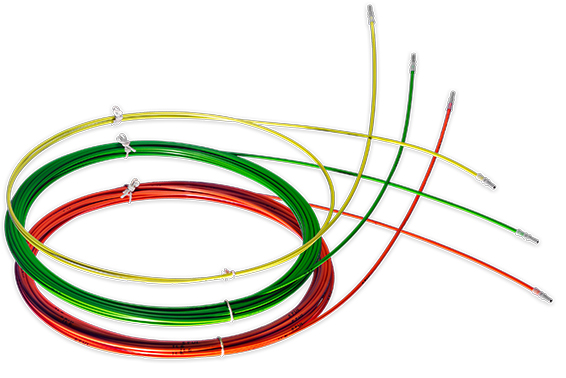

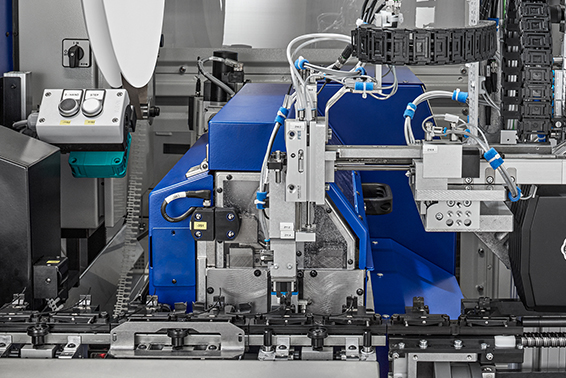

The high-performance cable processing machine from Schaefer GmbH, Germany is used for the production of quality POF cables, for example for the automotive industry. Welded connections with high precision and low light attenuation are produced fully automatically on the prepared wires. The special properties of polymer optical fibers require parameters and processes specially adapted to the material. Schäfer has many years of experience in the development and manufacture of tools and machines in this technology. The basis of the fully automatic cable processing machine is a transfer system which transports the wires to the respective stations with shuttles. Connecting the polymer optical fibers Connections of the wires with fiber optic terminals are performed at the welding stations of the processing machine. Standard fiber optic ferrules as well as special pin and socket terminals (pigtails) can be attached. For quality assurance, the integrated fiber measurement monitors each welded connection. Additionally, the quality-relevant light attenuation is measured during ongoing production. Cables with measured values outside the specified tolerances are automatically sorted out and made unusable for the rest of the process. With a high production rate and quality assurance functions, the machine is suitable for series production. The high grade components, the robust machine design and the modular construction stand for highest product quality, short set-up times and durability.

Overview of the overall process

The individual processing steps on the wires are:

- Unwinding

- Printing

- Cutting to length

- Processing of the end face

- Winding and binding

- Mounting of protective caps

- Laser welding with terminals

- Measuring core residue

- Measuring attenuation

Industries Served / Applications :

Aerospace, Defence, Military, Automotive, Industrial Automation, Medical, Solar Photovoltaic, Railways, E-Mobility, Renewable Energy, Telecommunication