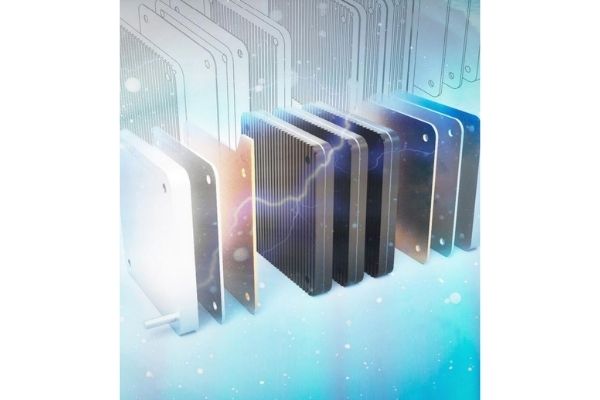

Surface AOI Inspection in Fuel Cell Production

The transport revolution is here. Alongside electric cars, vehicles powered by fuel cells will soon be taking over our roads—producing steam as their only emission. For the automotive industry, fuel cell technology means moving to new, challenging markets. If you want to assert yourself in the market, your quality standards must set you apart from competitor’s right from the get-go. We’ll show you how inline inspection can support your production of fuel cell components and stacks.

Inspection Systems You Can Rely On

Our systems automatically detect all surface defects in bipolar plates (BPP), membrane electrode assemblies (MEA), and gas diffusion layers (GDL). The systems inspect the components before or during their assembly into a stack. Of course, you can also use them for inbound or outbound inspection. They reliably detect even the smallest defects—at full production speed. That’s something you can rely on.

Even the smallest deviations impact quality and, in turn, the profitability, safety, and sustainability of your fuel cell production. Our VINSPEC systems monitor all relevant quality criteria with automatic, objective, and reliable inspection.