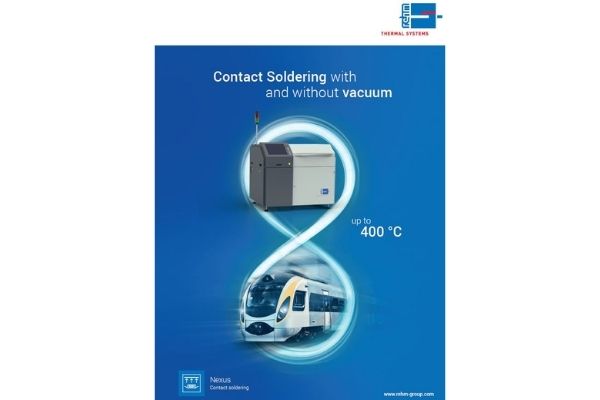

Contact Soldering-Nexus

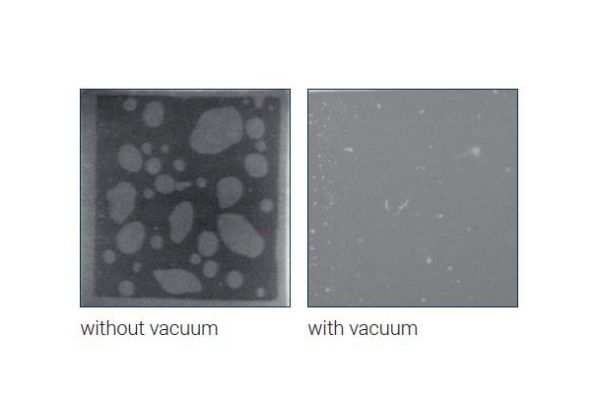

Nexus Contact Soldering System – with and without vacuum Void-free soldering with vacuum | Ideal for a great variety of applications

Shrinkage-free soldering of pastes and preforms

The Nexus is specially designed for flux-free vacuum soldering of pastes and preforms. Here, the Nexus works with temperatures of up to 400°C. These high temperatures are necessary in order to ensure that the materials, which are usually highly dissimilar are fused securely. The reduced pressure helps, among other things, to minimise oxidation on the components and on the solder itself. The heat is transferred both via thermal conduction and optionally by radiation too with the Nexus. Individually adjustable heating and cooking gradients ensure flexible processing and make short process times possible. In accordance with the respective customer requirements, different process gases maybe used. Flux-free operation with up to 100% nitrogen, forming gas (95/5), formic acid or up to 5% hydrogen is therefore possible. Should soldering paste containing soldering flux be used, the process gas is cleaned efficiently via the residue management system. Its compact dimensions and high level of user-friendliness mean that the Nexus system is particularly suitable for use in small-scale and medium-scale production, as well as in laboratories.

Nexus features:

- Oxide and void-free joint surface between chip and interconnected device

- Integrated or separate cleaning and de-scaling processes

- Simple profiling and fast heating and cooling rates

- Assembly under high level of vacuum

- Integration of drying and degassing processes

- Optimum dispersal of waste heat

The Nexus contact soldering system is best suited for void-free soldering of different devices (e.g. IGBT) on DCB substrates. The combining of materials that are normally highly dissimilar takes place in the vacuum at a reduced pressure at temperatures up to 400 °C (optional 450 °C). The reduced pressure thereby helps to minimise oxidation on the components and on the solder itself. The transfer of heat is via heat contact surfaces or optional by radiation

- Heating and cooling on a usable area of 500 mm x 500 mm

- Clearance of 100 mm above heating plate

- operating temperature 400 °C*, optional up to 450 °C

- Heating rate max. 150 K/min*, cooling rate max. 180 K/min*

- Vacuum up to 1mbar (optional 0,1 mbar)

- Fluxless activation with different gases possible

- One gas line for N2 with pressure regulator and gas monitoring; proportional valve

- Each gas supply line is equipped with a switch to save purging gas while the machine is not in use

- The vacuum system can be equipped with adjustable flow ratios. The volumetric flow rate for process gases is adjustable and controlled by a proportional valve.

- Fluxless operation with 100 % nitrogen, forming gas, formic acid or up to 100 % hydrogen

- Formic acid bubbler with fill level compensation to keep the saturation always at the same level (saturation level of N2 depends on the fill level of the bubbler)

- Optional Residue Management System for use with solder paste