Convection Soldering

Convection Soldering: Vision Series

Modular Systems for every manufacturing environment

For full functionality of sensitive electronics, contact between the electrical components and the circuit board, created by high-quality soldering, is essential. With the convection soldering systems in the Vision series, the soldering process is carried out on the basis of heat transfer via the flow of gases. The systems are available as air or nitrogen systems. As an inert, protective gas, nitrogen is the ideal heat transfer medium and thus prevents damaging oxidation in the soldering process. Thanks to a wide range of possible system configurations, you achieve optimum quality with the Vision series convection soldering systems, as well as maximum flexibility in terms of your production.

Why convection?

- Maximum process stability, even with unleaded soldering

- Modular, flexible system concept

- Energy-efficient systems with low CO2 emissions

- Minimum downtime and low maintenance costs

- Excellent traceability thanks to clever software tools

- Low “Total Cost of Ownership”

Convection Soldering Systems:

Vision TripleX: The 3-in-1 solution for your soldering process

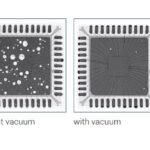

- The 3-in-1 solution for void-free reflow soldering

- Combination of convection soldering with and without vacuum and vapour phase soldering

- Vacuum down to 10 mbar for reducing the number of voids in the solder joints

- Removes pores and voids immediately after the soldering process reliably and vibration free

VisionXP+ | VisionXP+Vac: High-End convection soldering

- Efficient reflow convection soldering process at highest process stability

- Industry 4.0

- Vacuum down to 10 mbar for reducing the number of voids in the solder joints

- Efficient residue management with pyrolysis

- Highest energy efficiency with reflow soldering

VisionXS: Convection soldering for Mid-Range applications

- Modular system concept

- Efficient heat transfer

- Stable process for lead-free applications

- Minimal downtime

- Integrated residue management

- User-friendly software tools for process monitoring

VisionXC: Convection soldering with compact design

- Optimized heat transfer and thermal stability

- Excellent process performance at minimal space

- Efficient residue management system for a clean process chamber