Conformal Coating

Protecto series: Protective coating for multifunctional applications Protective lacquer coating with a focus on what matters most

Optimum coating processes for high-quality electronics

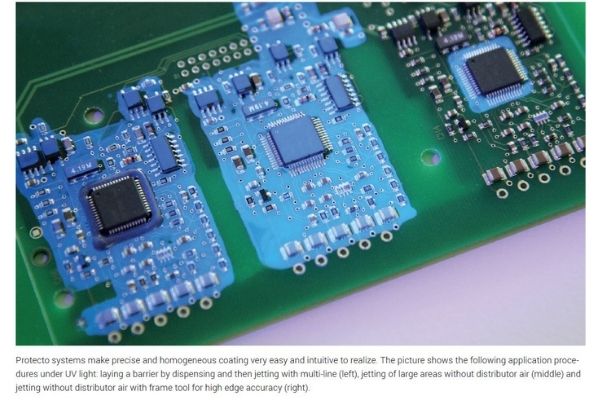

Our dispensing and coating systems ProtectoXP and ProtectoXC protect electronic assemblies from aggressive environmental influences such as moisture, corrosion, chemicals, dust or vibrations. The coating of the printed circuit board after soldering ensures the functionality of the electronic assemblies, which are processed, for example, in vital technical end products in the automotive industry, aviation or medical technology.

The coating systems by Rehm are impressive thanks to their process reliability and thus maintain the functionality of the circuit board on a long-term basis. For a particularly flexible and efficiently designed production, the Protecto systems are also available as line solutions with an RDS coating dryer, including handling according to customer specifications.

Why protective coating with Protecto?

- Maximum process reliability

- All-in-one coating

- Multifunctional lacquer applicator

- Selective coating

- Long-term lacquer application without any errors

- Minimal maintenance costs

- Also available as a line concept

- Smart software

Protecto Conformal Coating Systems:

ProtectoXP: Full power for your turnkey solution

- Greatest possible process reliability

- Flexible lacquering options thanks to a wide range of options

- Highly selective coating

ProtectoXC: Perfect performance – even at small lot sizes

- Reliable coating process

- Compact unit for easy integration

- Optimum process documentation

Application possibilities with ProtectoXP/XC:

With the Protecto systems, completely new application fields are emerging – even outside of the conformal coating sector. Thanks to the highly flexible system construction, you can use ProtectoXC to combine for three and ProtectoXP for four processes within one machine. In addition to sealing the entire circuit board, partial areas or individual components can also be coated on the support.

- Dam & Fill / 3D-Application

- Sealing

- Globe Top

- Flip Chip Underfill

- 2K Encapsulation

- Heat dissipation

- Individual requirements